The project in detail

Kedleston Hall is coming to the end of a huge restoration project of the state interiors, a project that has been ongoing since the National Trust acquired the house in the late 1980s. The state bed is one of the last pieces in this jigsaw of work which aims to restore the interiors to how they were when the house was built in 1765 designed by Robert Adam. The Curzon family, whose ancestors commissioned the house still live in the East wing to this day. In the 1960’s the family had the walls recovered in a copy of the original silk damask, however the damask was not an exact historical replica being made out of cotton and woven to a different loom-width.

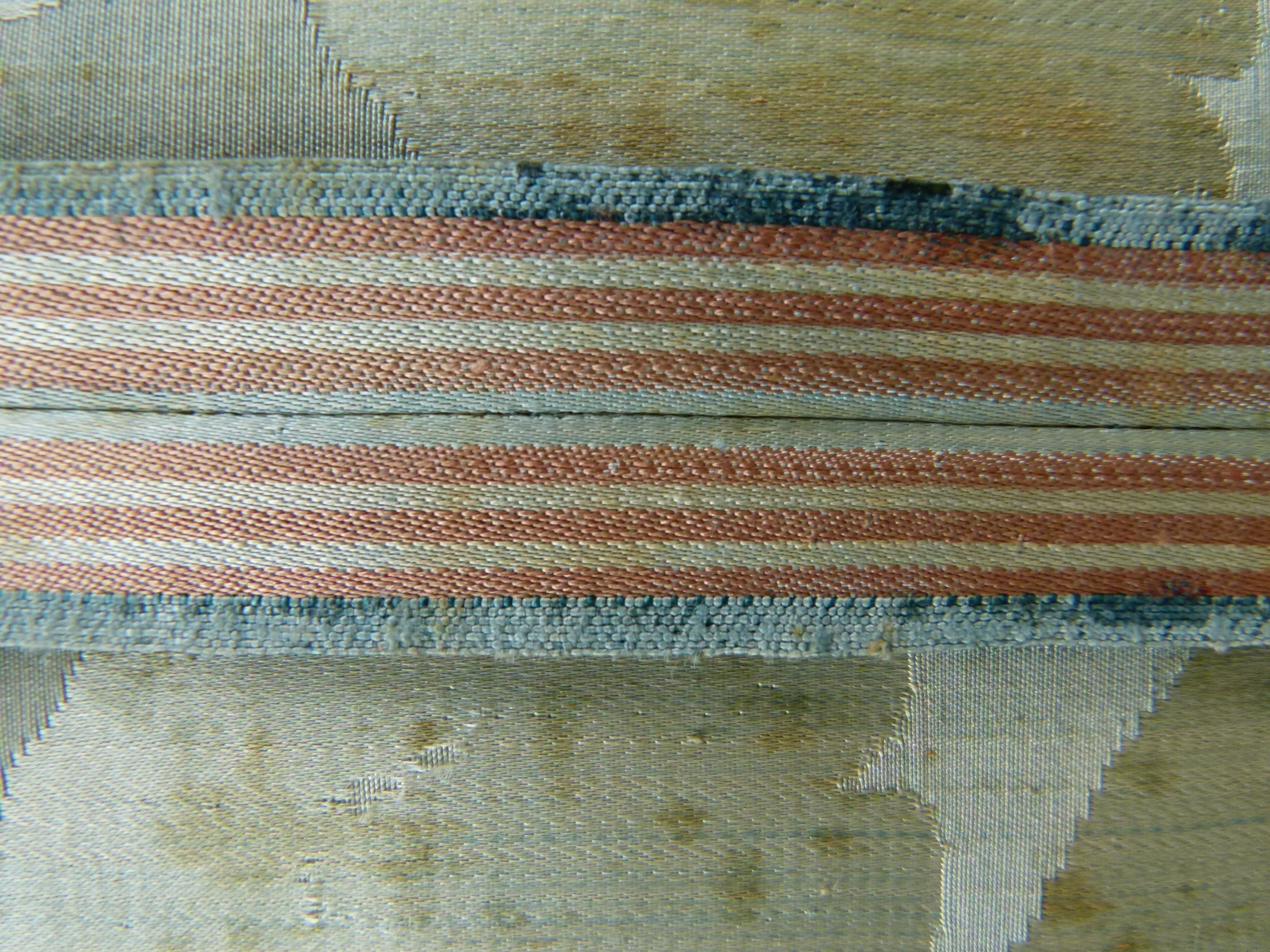

A scrap of the original damask was found enabling the National Trust to create an exact replica and in 2009 one mile of silk damask was woven in the original loom-width of 21” by Humphries Weaving in Suffolk. This replica silk has now been used to cover the walls and furniture throughout the state rooms and finally now the state bed. It wasn’t until taking down the bed that it was discovered that the silk inside the tester was the original 18 century silk – and while faded, was in remarkably good condition. It was felt very important that this original silk was not damaged, as very little remains in the house.

It was at this point that we were brought in; the brief being to re-cover the inside of the tester with replica silk whilst preserving the original beneath. The tester was delivered to us having had the gold mouldings removed and the back panel loosened by the furniture conservation team at Tankerdale Ltd. Once we had surface cleaned the tester, the back panel was removed to give us access from the middle of the tester which was necessary due to its size and shape.

The new silk needed to be held in close contact with the original and needed to exactly match the concave, curving shape of the tester. However to adhere it directly to the original silk would be too damaging – the challenge was how to do this without compromising the original silk at all. We needed to make a lightweight, inert, rigid shell exactly following the contours of the tester. This shell would slot on top of the original silk, protecting it beneath whilst giving a surface for the replica silk to be adhered to.

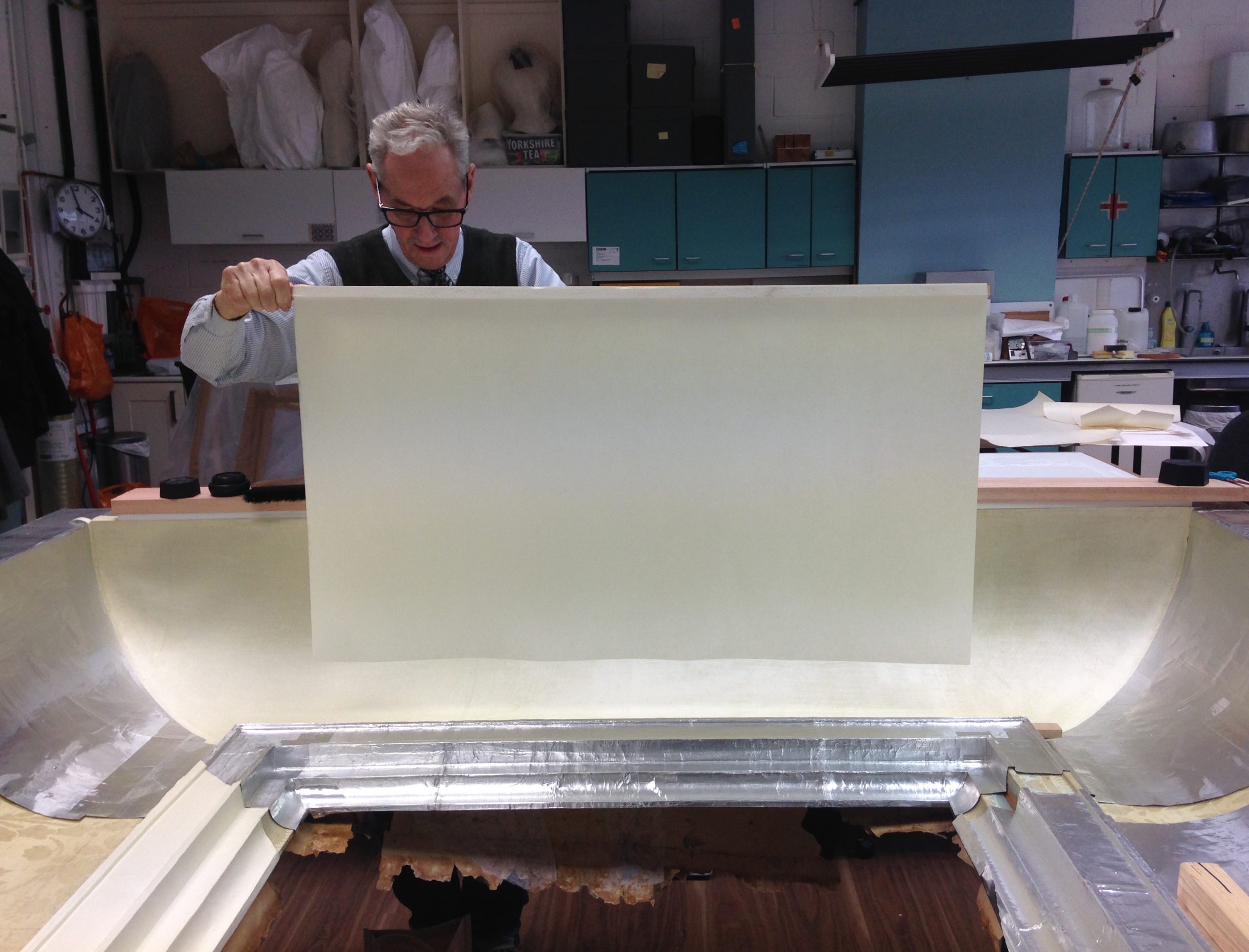

After a great deal of experimentation and testing it was decided that layers of Japanese paper laminated together using wheat starch paste formed a strong yet thin shell which exactly followed the curves and sharp steps of the tester, without altering the dimensions by more than a few millimetres. This was extremely important as the gold mouldings had to fit tightly back into exactly the same position so that they could “read” correctly and could be reattached using the original tack holes. The laminated Japanese tissue would form an inert and archivally stable layer between the original and replica silk. The shell would also flex enough so that it could be removed quite easily from the tester if desired. Laminated Japanese paper is exceptionally strong and has been used traditionally to bend and shape both wood and steel!

The original silk was first covered in industrial strength aluminium foil to protect the silk from the damp wheat starch paste. The foil was rigid enough to hold the concave shape of the tester whilst also being capable of moulding sharply and accurately around the narrow steps of the design.

Forming each of the four paper sides of the tester in Japanese paper took two conservators (both with paper conservation experience) one long day to make plus preparation time cutting the paper to size beforehand and a further two days carefully and slowly drying the paper shell afterwards. It proved crucial that each side was completely dry before the blotters and weights were removed otherwise the shell would immediately pull itself out of shape and require re-wetting and weighting.

Once all four sides were completely dry, the replica silk could be carefully aligned and applied using manufactured Beva® film, reactivated using heat. The pattern of the original silk was exactly matched on the large curved and flat central panels. However due to a shortage in replica fabric remaining, it was decided this level of accuracy was not essential for the stepped areas of the tester which are hidden by the gold mouldings. It was decided not to join the four silk covered sections together into one as this will give easier access to the original silk damask behind should anyone want to study it in the future.

The tester and new silk covered shells were returned to Tankerdale Ltd where the whole spectacular tester was skillfully reassembled by their furniture conservation team following the conservation of the mouldings themselves. These were re-pinned in place as they had been originally, hiding the joins in the new silk shell and holding the whole thing snugly in place. Gavin Repton documented the whole conservation process for the National Trust – watch below.